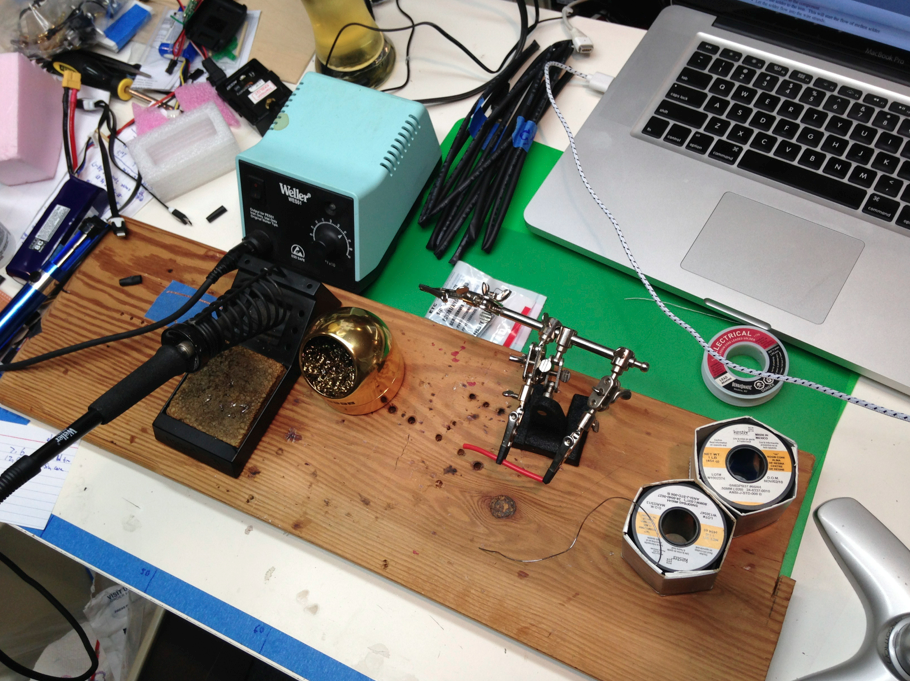

Solder the male pins down each long row.

- Put the pins in the breadboard.

- Long end of pins go into the breadboard.

- Line up the Arduino Micro so that it sits on the pins.

- CPU goes on top.

Assemble The Arduino Mini

Solder the male pins down each row. Same as for the Micro.

Solder the end pins.

Solder the male pins down each row. Same as for the Micro.

Solder the end pins.

- Those are the 90 degree pins.

- They go into the 6 through holes on the short end.

- Use the helping hands.

- Flip the board over, the CPU should be on the bottom.

- The short end of the 90 degree pins should come through the holes.