RCGroups thread:

Midelic Firmware thread:

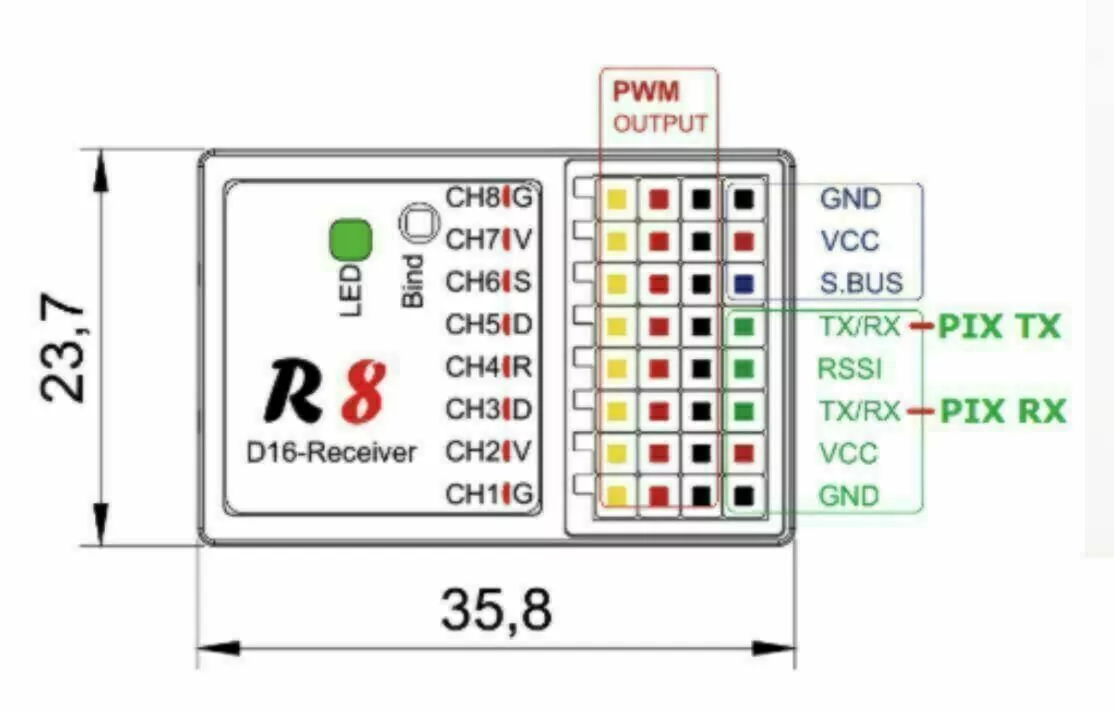

- Jumper R8 Receiver - 8-channel PPM/16 channel SBUS, D16 /LBT/D8 compatible firmware

- DIY FrSky X(D16) receiver - RC Groups

STM Flasher and Tutorial

- FLASHER-STM32 - STM32 Flash loader demonstrator (UM0462) - STMicroelectronics

- Flashing programs to STM32. Embedded Bootloader | Do It Easy With ScienceProg

- New All-in-one Software Tool from STMicroelectronics Makes STM32 Microcontroller Programming More User-Friendly

For STM STM32CubeProg on Mac:

Double clicking the installed app just bonces the icon in the dock once and then quits . You can get it to run by right clicking on the installed package (STM32CubeProgrammer.app), selecting 'Show package contents' and navigating to Contents/MacOs/bin/STM32CubeProgrammer and right clicking 'open'.

CPU:

- STM32 F103C8T6 6Q25E 1193

LED colors

- steady green: signal good

- blinking green: signal bad

- solid red: signal low

- blinking green: signal bad

- solid red: signal lost

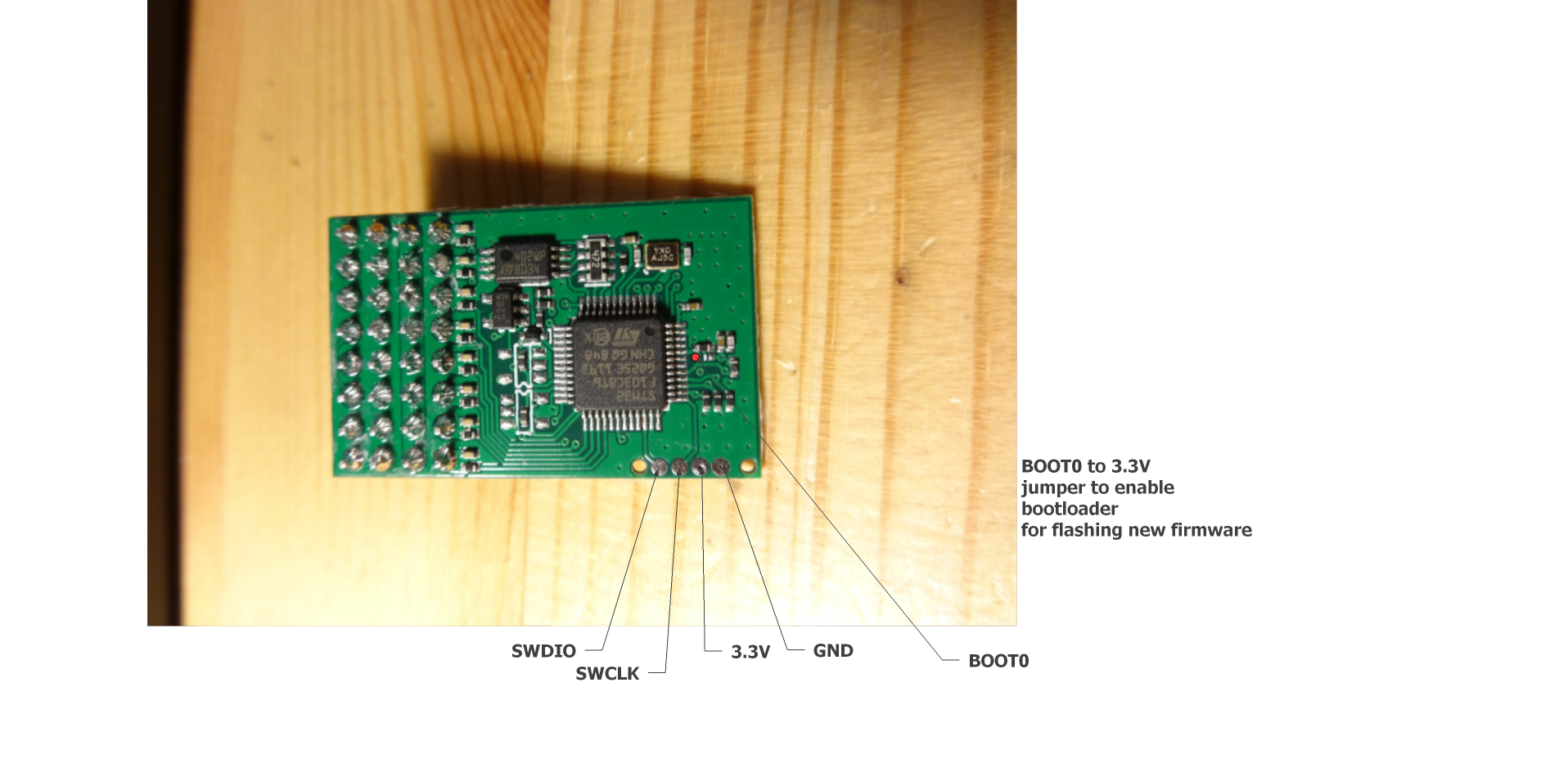

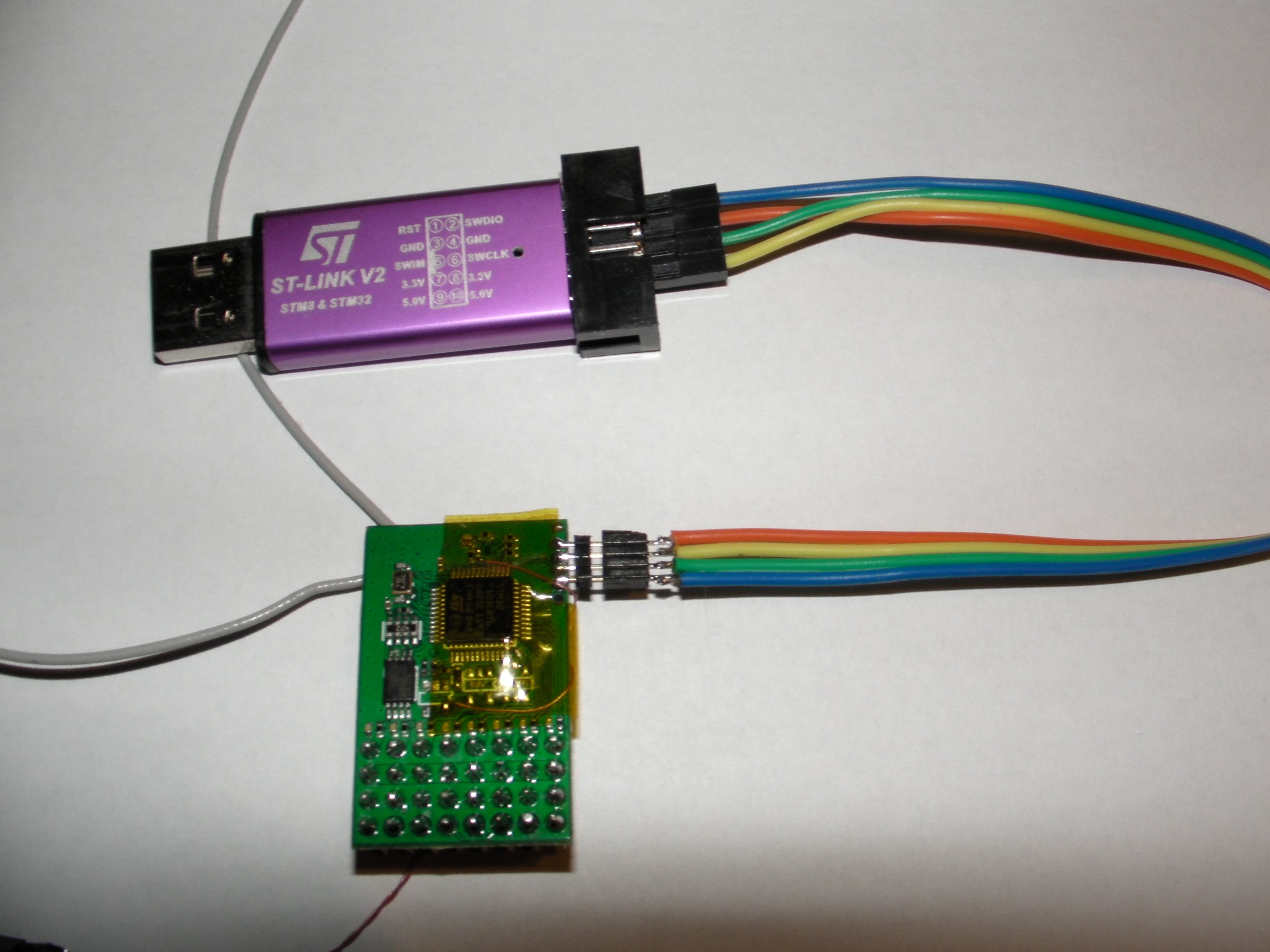

Flashing new firmware on Jumper R8 connections.

- Use STlink V2 programmer.

- connect STLink device ,press Target/connect.

- If you receive "Read out protection" enabled warning, go into "Option bytes" and disable it.

- Press "Erase/Chip" after that press "Program&verify" load the binary file to be flashed.