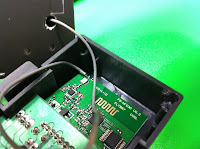

Continuing from part 1... here's the power cable attached to the bottom of the board.

Continuing from part 1... here's the power cable attached to the bottom of the board. Check the voltage on the power pads, you should see full battery voltage. You'll also notice that the positive pad is on the right looking down with the arm pointed at you.

Check the voltage on the power pads, you should see full battery voltage. You'll also notice that the positive pad is on the right looking down with the arm pointed at you.A lot of ESC wiring needs to be cut off in order to solder the ESC directly onto the frame. It turns out this is a lot easier than it looks, so don't sweat it.

Here's about how much to cut off for the power. Put a blob of solder onto the pads, then cut and tin the ESC power wires. Position the wired onto the blobs, touch your soldering iron to the wire, and the tinning solder melds smoothly with the blob on pads.

Trimming the shrinkwrap a bit helped.

To verify, plug in the battery and measure the voltage on the control cable. it should be about 5 volts.

Do the same thing to the three motor leads of the ESC.

Do whatever programming (if any) is necessary on your quad controller board. My notes on doing this for a KK Board are here.

It seems you're supposed to attach the KK Board (if that's what you're using) onto the leg bolts, but they're too short. I used a triple layer of double-sided servo tape.

Attach your receiver and hook up your motors to the quad controller board.

Now here's a very weird thing. I trimmed the motor wires just as I trimmed the ESC wires, but I could not get the to tin at all. I have no idea why this was -- are the wires coated? Anyways, I mashed the wires into the solder. I'm hoping this is good enough... if not and I have a cold solder joint I'll try and figure out the solder problem or buy another motor.

Fortunately, I had done just the one motor as an experiment. For the other three motors, I tinned the ends without cutting the wire, and attached them while just folding the wires back.

This worked well and is what I recommend you do. (update: brosius85 points out that the motor windings are coated with varnish that's heat-resistant in order to handle the high temperatures of the motor. That's why I couldn't just burn off the coating with the soldering iron. Thanks Brosius85!)

Continued in part 3...