Jack Erbes is one of the modern day geniuses of foamy construction. Here's his RCG build log of a KFM3 wing for the Blu Baby. My BB32 wings broke in half, so I'm especially interested in this. I'll lightly edit, but the first person voice is Jack's. I'll try this later and do my own writeup if I think it might be useful. Jack writes:

I recently made a KFm2 wing with polyhedral tips for use on my KFoenix Stick and flew it in RET configuration (Rubber, Elevator, & Throttle, no ailerons) and was really impressed with it. It had excellent tracking and control and good rudder authority, which had been a problem with the stock Slow Stick wings. The wing seem to "lean into" the turns nicely as speed increased and as turns were made more aggressively. It was almost as if I were flying a wing with ailerons.

I recently made a KFm2 wing with polyhedral tips for use on my KFoenix Stick and flew it in RET configuration (Rubber, Elevator, & Throttle, no ailerons) and was really impressed with it. It had excellent tracking and control and good rudder authority, which had been a problem with the stock Slow Stick wings. The wing seem to "lean into" the turns nicely as speed increased and as turns were made more aggressively. It was almost as if I were flying a wing with ailerons.

Jack's Instructions are as follows:

The flat center section/polyhedral tip wings are a quick and easy build and have better inherent strength than the two panel wings with dihedral that have a center joint. And I've also found that the flat wings like this have much less need for a spar because the multiple and full width gluing lines create a monocoque structure with very good strength. As an example, the 48" span 11-1/2" chord wing I made for the KFoenix Sticks has two 1/4" dowels (36 grams for the two dowels, and only about $1.50 in cost) and probably has more inherent strength than it will ever need.

So I wanted to get a BB 33 back into a better advanced trainer and sports flyer configuration and decided to make a 33" KFm3 wing with polyhedral tips for it.

Materials:

1 24" x 48" sheet of FFF (Dow Protection Board III insulation, from Lowes or Home Depot)

1 3/16" x 36" wooden dowel (any wood will work)

Gorilla White Quick glue (any PU glue will work)

Clear package sealing tape (Duck brand "Standard" weight is good)

Colored package sealing tape for final covering/decoration/improved visibility in flight (final covering and colored tape is optional, but it contributes to strength and is very eye pleasing).

Clear Duck tape (fabric reinforced tape, any color would work but I would not be caught dead with a RC plane with the standard gray or silver tape on it)

Bamboo skewers for trailing edge reinforcement at wing center

Optional parts:

1/8" wood dowel or 2mm fibreglas rod for leading edge reinforcement

All of the wing parts are seen in this photo, from the top down they are:

- KFm3 50% strip

- Filler strip

- 3/16" x 36" wooden dowel (Crafts section at Wal-Mart)

- KFm3 75% strip (also supports the 50% step)

- Wing panel for KFm3 Sport wing

The wing panel can be made without the templates from piece of foam that is 33" wide and 8" high. Simply mark two points 15-1/2" in from each end (that leaves a the 2" section in the wing center that is over the fuselage), then mark two points 7-1/2" back from the leading edge on the wing tips. Cut a straight lines from the marks on the wing tips to the marks near the wing center and that is the one piece wing panel.

The wing panel can be made without the templates from piece of foam that is 33" wide and 8" high. Simply mark two points 15-1/2" in from each end (that leaves a the 2" section in the wing center that is over the fuselage), then mark two points 7-1/2" back from the leading edge on the wing tips. Cut a straight lines from the marks on the wing tips to the marks near the wing center and that is the one piece wing panel.The wing panel is skin side down, the KFm3 50% strip is skin side up, decide that arrangement now and turn the KFm3 50% strip over skin side down. Cut 45 degree or so bevels on what will be the leading edges of the wing panel and the KFm3 50% strip when the two are taped together. The bevels allow the edges of the foam to bend and curl downward a little as the pieces are taped and folded to form the leading edge. The leading edge will be slightly rounded "V" and not sharp. A sharp leading edge is not wanted or needed on a slow flying plane like the BB 33 and a sharp leading edge is also be easily damaged.

To join the wing panel and KFm3 50% strip, lay a 36" or so long strip of the clear package sealing tap out with the sticky side up. I tape the right end down and the weight of the roll of tape keeps it straight and flat. Lay the wing panel so it is on the bottom 3/4" of the tape and press it down and into good adhesion with the tape. That is what has been done already in this photo. Note the faint lines drawn across the wing panel at this point. The two lower lines are drawn with a fine tip Sharpie across marks that were 3-3/4" and 5-5/8" back from the leading edge at the wing tips. They are the eventual locations of the 50% and 75% steps. The line up near the leading edge is 3/4" back from the leading edge and is where the front edge of the filler strip will be when it is glued to the wing panel.

The 50% KFm3 strip has been laid on the upper half of the exposed tape with a even gap of a little less than 1/4" all the way across. I know from previous experience that the gap needs to be that wide for foam of this thickness and I used the 3/16" dowel that will be the main spar to judge the gap and keep it even all the way across. The spar is not glued there, it is just to keep the gap right and even.

Cut the tape even with the foam on both ends and turn the joined panels over. Smooth the tape into contact with the skin side of the foam. The adhesion of the tape to the skin is very good, you are unlikely to be able to separate them without damaging the foam, removing the skin, or both. I put one or two more strips of tape over the fold area to strengthen it more. If I use one piece I just center it on the first strip. If you use two strips I arrange one so it is 1/2" above the upper edge of the first piece of tape and the second so it is 1/2" below the lower edge. That will give you either two to three layers of tape on the leading and, for a very small amount of weight added, you will have a very durable leading edge and a stronger joint at the fold.

Then turn the wing panel back over and drop the 1/8" dowel into the gap between the wing panel and the KFm3 50% strip. The lift the 50% strip up to check the tension on the tape. If the gap was about right the foam will come up to just slightly beyond vertical when you start to feel some pulling tension on the tape. The weight of the utility knife leaning on the foam is holding the foam back as seen there If it all feels about right, lay a board that is about 33" long against the foam and fold it all the way back until it is laying flat on the top of the wing panel. It will resist folding back and some force will be needed but this is the step that finalizes and forms the leading edge.

The line I drew on the wing panel to mark the back edge of the filler strip was spritzed with a fine spray plant sprayer. Spritz the area where the filler will be in contact all the way across, you can't get things too wet for PU and the glue will not work worth a darn if you do not use water. Lay the filler strip bottom side up, put a small bead of PU glue down the length of it, and then spread it evenly across the filler strip with a flat flexible plastic spreader. I use spreaders cut from the plastic snap-on lids of food containers. When spread evenly there will a slightly shiny appearance across the width of the strip. Position the strip even with the line, press it into contact with your fingers, and then weight it down all the way across the strip. Make sure to get weight all the way across and on the ends or the foaming action of the PU glue will lift the strip up. Check it several times in the first few minutes to make sure the strip does not slide out of contact. If you don't do that the "crooked gluing with PU fairies" will sneak in and push the stuff around to make you look bad. Give it about 10-15 minutes (with Gorilla Quick PU) and you can remove the weights and get on with the job. Any foam outs or ooze here are not a concern. They are handy for telling when the glue is set. When you can push the foam outs down flat with your finger and none of it sticks to you it is set up enough.

The filler strip has been glued down in this photo and the KFm3 75% strip is laying bottom (bare foam) side up and will be glued down next. It will be aligned with the faintly seen line I drew earlier and that will form the 75% step.

The contact area where the 75% strip will contact the wing panel got spritzed with water, two beads of PU were run the length of the back of the 75% strip, that was spread evenly with the flexible plastic spreader, and the 75% strip was brought into alignment with the line and pressed down to contact the wing panel. Plenty of weight was added to keep things in contact as the glue foamed up and I kept a watchful eye open to make sure the strip did not move around in the first few minutes.

I have some 2mm fibreglass rods that came out of kites that make for good leading edge reinforcements so I decided to drop one into the leading edge here instead of the 1/8" dowel. These rods will let you whack leaves off of trees and even trim the smaller new growth if you have enough speed. They are also handy for ringing trash barrels and administering punishment to dogs that are foolish enough to think that it is OK to catch airplanes. Since I am going to bend the wing tips up for dihedral I cut the 2mm rods short enough (20" long in this case) to be only on the flat portion of the leading edge The 3/16" dowel that is the main spar is also seen in this photo, it will be rolled back to the right and against the leading edge of the 75% strip when the wing is closed. The dowel and the 75% strip will both get some PU glue on them and foam will build up around them and create a second full span glue line to join the one formed by the filler strip.

OK, both the strips are glued down and we can get ready to close the wing up. PU glue sticks best to bare foam. So the plastic skin needs to be removed from the top of the filler strip if it is still there. Fold the KFm2 50% strip back again (I use that board again to help with that) and, while it is held down flat against the top of the 75% strip, a line is drawn across the wing right at the 50% line. Then let it fold up out of the way again.

The line is faintly seen here, it marks the area where the 50% strip will rest on top of the 75% strip. Use the tip of the utility knife to make a very light cut along the line (just deep enough to cut through the skin) and peel the skin off of the area where the 50% strip will rest on the 75% strip. If you lift the skin up at a shallow angle as seen here it will come off in one piece, if you lift it too steeply the skin will tear when it encounters the pinholes in the skin and be a lot harder to remove.

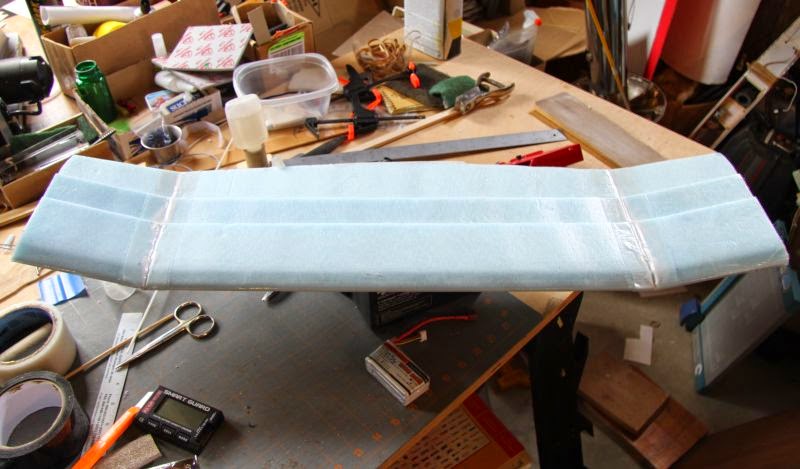

And there it is, a fully closed flat, KFm3 wing. You just wanted a good flat and sporty aileron wing, this would be a good stopping point on the wing build. Cut your ailerons out and finish it up that way. The wing is about 80 grams at this point, if I had left the 3/16" dowel and the 2mm fibreglass rod out it would be about 60 grams.

I used a utility knife to cut a "V" groove from the 75% step back to the trailing edge. The depth of this groove was about 1/2 of the thickness of the single layer of foam.

The wing after both tips are cut, folded up, and glued.

Here is a little sneak preview of "Old Yeller" trying on his new wing (only lacking tip plates at this point). That is the plane will get a chance to test the polyhedral wing here in the near future.

No comments:

Post a Comment